Your What is the proper way to splice a truck frame images are available. What is the proper way to splice a truck frame are a topic that is being searched for and liked by netizens today. You can Get the What is the proper way to splice a truck frame files here. Get all royalty-free vectors.

If you’re looking for what is the proper way to splice a truck frame images information connected with to the what is the proper way to splice a truck frame keyword, you have pay a visit to the right site. Our website frequently gives you suggestions for refferencing the highest quality video and picture content, please kindly search and locate more informative video articles and graphics that match your interests.

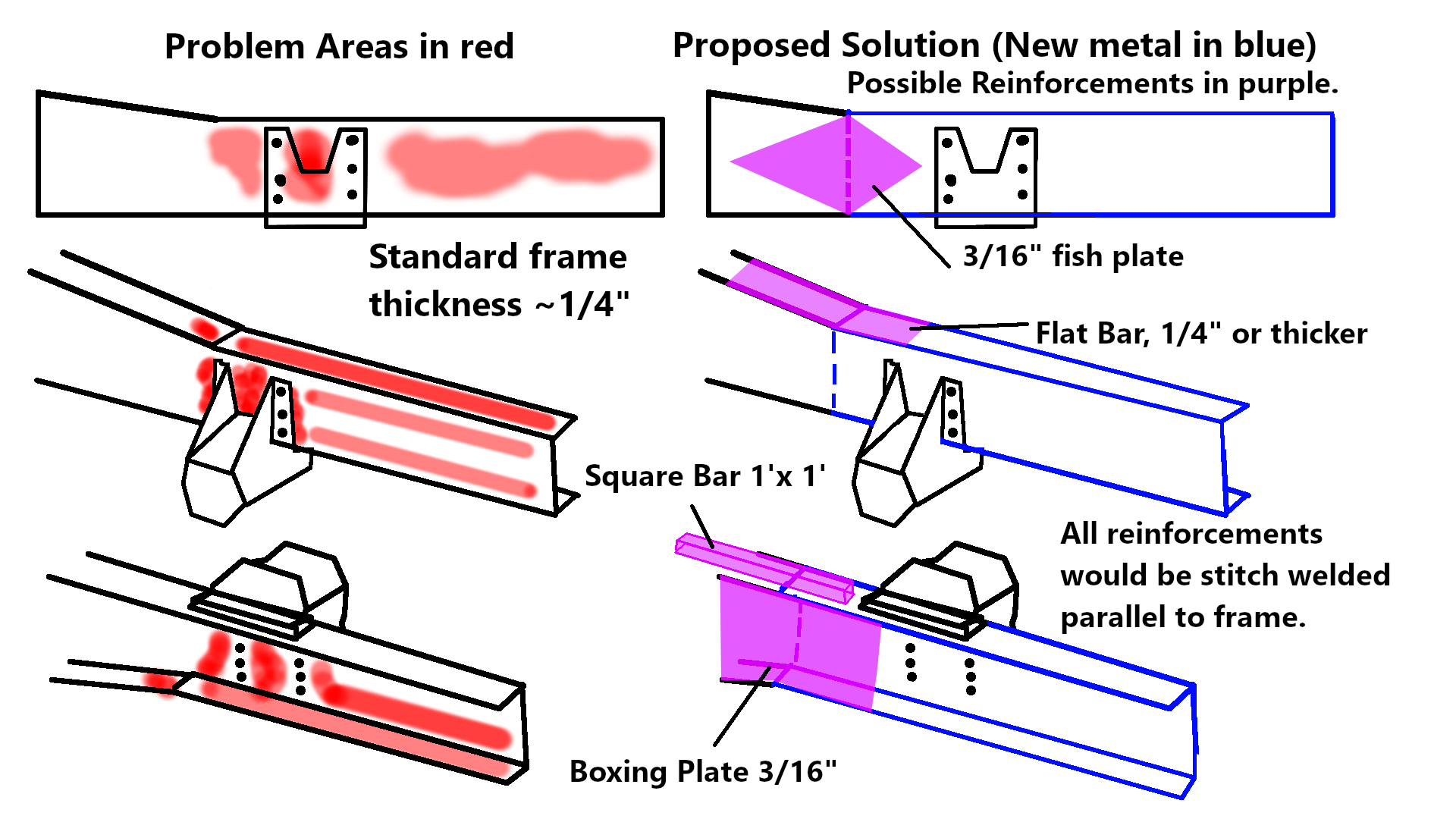

What Is The Proper Way To Splice A Truck Frame. Otherwise use new frame rail for the addition such that you only have one weld. It supports all the running gear of the vehicle including the engine transmission rear axle assembly in a rear-wheel drive and all suspension components. Keep an eye out for damage like blistering or cracking. Given so many components are involved the process of lengthening your frame can get complicated.

Which frame splice is the strongest. Frames are not all that thick in most cases they will be 38 or less so often times there will only be a need for 1 pass inside and 1 pass outside. Basically two 45 degree lines that X in the middle of the frame. 5000 for the whole shebang done right with correct cross members and drivelines. Volvo recommends a taper of 20-30 degrees. I know vert welds are a no-no.

In this video we make some more progress on the beverage body frame.

Tapering Staggering Essential in Frame Splicing. A lot of people do a step cut or a angle but I always cut a 90 degree angle. Perhaps the best way to remove the sample from the frame is to use a hole saw or Hougen type drill that removes a slug. Set the vehicle on a frame-pulling device along with a 3-D measuring system. One constant however was to stay away from a 90 buttweld. Then weld the top flange the same way.

Source: weldingtroop.com

Source: weldingtroop.com

Which frame splice is the strongest. Keep an eye out for damage like blistering or cracking. AT one point during his Truck Frame Overview For Body Mounting session Dick Toner asked for a show of hands. Frames are not all that thick in most cases they will be 38 or less so often times there will only be a need for 1 pass inside and 1 pass outside. Just adding a tail out to the end of your weld wont be as effective as having the weld tail out merge into the original weld 1 or 2 inches past the end of the fishplate.

Source: ford-trucks.com

Source: ford-trucks.com

Drill the hole through the web where is is least likely to reduce the usefulness of the frame. My plan is to cut a. Any rusty parts will have to be cut away with a grinder hacksaw or a torch. Im looking at lengthening a frame approximately 2 ft. That type of splice is how I plan to join the front and rear halfs of the truck Im building a crew cab with an extended cab rear section added on using the rear 23 of one frame and front half of the other with the splice going under the.

20 degrees is 27 times the frame height and 30 degrees is 17 times the frame height. AT one point during his Truck Frame Overview For Body Mounting session Dick Toner asked for a show of hands. On frame splices he said the general rule is that reinforcements should taper a minimum of two times the frame height. Before welding pre-heat frame rails on both sides of splice 6 to 10 inches keeping heat from 75 to 175 degrees. To lengthen a truck we found another truck to rob frame and suspension that would add to what he had for the correct length with just one weld.

Source: comancheclub.com

Source: comancheclub.com

Ford Collision Repair Information Available. On frame splices he said the general rule is that reinforcements should taper a minimum of two times the frame height. Volvo recommends a taper of 20-30 degrees. I know vert welds are a no-no. Given so many components are involved the process of lengthening your frame can get complicated.

Source: weldingtroop.com

Source: weldingtroop.com

This crossmember helps get the frame lower by about 1-12 to 2 compared to a stock Model A crossmember. It supports all the running gear of the vehicle including the engine transmission rear axle assembly in a rear-wheel drive and all suspension components. On frame splices he said the general rule is that reinforcements should taper a minimum of two times the frame height. Volvo recommends a taper of 20-30 degrees. Volvo recommends a taper of 20-30 degrees.

Rosette weldspot weld minimum four spots per side of each rail plus leave about 18 gap between rails with a bevel on rails to make full penetration with sleeve when fully welded together. Given so many components are involved the process of lengthening your frame can get complicated. Any rusty parts will have to be cut away with a grinder hacksaw or a torch. If your drill bit is sharp yohappymugsu will bepleasantly surprised how easy it is. Drill the hole through the web where is is least likely to reduce the usefulness of the frame.

Source: truckconversion.net

Source: truckconversion.net

First I would put punch marks on each side where you want the cut then if you were to take out 18 inches I would measure 10 in front and in back of those punch marks and put two new punch marks on each frame member. Use a good 12 or 58 inch drill motor with an extra handle with a GOOD step drill and wrap a chain around the frame and loop it around one of the handles on the drill motor and lean in on it. 04-25-2017 0709 PM. Then use your grinder and carefully grind the stringer to leave a nice even V for your next passes. Then weld the top flange the same way.

Basically two 45 degree lines that X in the middle of the frame. I cut the frame as a V laying on its side. 20 degrees is 27 times the frame height and 30 degrees is 17 times the frame height. When I spliced my frame I used an arrowhead cut on both pieces and I added fishplates inside which were plug welded. On frame splices he said the general rule is that reinforcements should taper a minimum of two times the frame height.

Source: youtube.com

Source: youtube.com

Any rusty parts will have to be cut away with a grinder hacksaw or a torch. In this video we make some more progress on the beverage body frame. Ford Collision Repair Information Available. Another thing to consider is not making the splice area too strong where it will create a weak spot right next to it. The front face of the crossmember is already formed.

Source: youtube.com

Source: youtube.com

Be sure and clean the ends of the welds before adding the next bead. Nextfrom the inside of the frame weld the transition corner of the V in the webFrom this point you may alternate welding inside outside top and bottom. Another thing to consider is not making the splice area too strong where it will create a weak spot right next to it. Then weld the top flange the same way. Then weld all the edges.

Source: forums.justoldtrucks.com

Source: forums.justoldtrucks.com

This crossmember helps get the frame lower by about 1-12 to 2 compared to a stock Model A crossmember. Just adding a tail out to the end of your weld wont be as effective as having the weld tail out merge into the original weld 1 or 2 inches past the end of the fishplate. Weld from the edgetowards the corner about half way. I know vert welds are a no-no. On frame splices he said the general rule is that reinforcements should taper a minimum of two times the frame height.

Source: hmfexpress.com

Source: hmfexpress.com

Youshould make as small a bead as possible for your root pass. For what a short standard truck cost it really aint too bad a deal. Before welding pre-heat frame rails on both sides of splice 6 to 10 inches keeping heat from 75 to 175 degrees. I cut the frame as a V laying on its side. 04-25-2017 0709 PM.

Source: forums.justoldtrucks.com

Source: forums.justoldtrucks.com

Weld from the edgetowards the corner about half way. The frame is your standard C type frame of about 020 thick metal. Two basic requirements of your truck frame. There are ways to do this properly if you decide to- where the frame is cut we would generally make a Z cut so the section has more weld length or surface area kinda like a puzzle piece. I know vert welds are a no-no.

Source: rvnetwork.com

Source: rvnetwork.com

Pull the vehicle to its proper datum length and center line. Volvo recommends a taper of 20-30 degrees. Im looking at lengthening a frame approximately 2 ft. Ford Collision Repair Information Available. That keeps the weld from being.

All wired aired and on the road. Devise a pulling plan. Another thing to consider is not making the splice area too strong where it will create a weak spot right next to it. All wired aired and on the road. First I would put punch marks on each side where you want the cut then if you were to take out 18 inches I would measure 10 in front and in back of those punch marks and put two new punch marks on each frame member.

Source: youtube.com

Source: youtube.com

Then weld all the edges. Volvo recommends a taper of 20-30 degrees. My plan is to cut a. Devise a pulling plan. Then use your grinder and carefully grind the stringer to leave a nice even V for your next passes.

Source: youtube.com

Source: youtube.com

The frame is your standard C type frame of about 020 thick metal. Yep here its common. The front face of the crossmember is already formed. In my quest of searching for the correct answer in preperation of a front frame splice I became thoroughly confused because everyone seemed to have a different opinion. I know vert welds are a no-no.

Drill the hole through the web where is is least likely to reduce the usefulness of the frame. If your drill bit is sharp yohappymugsu will bepleasantly surprised how easy it is. Yep here its common. 04-25-2017 0709 PM. I cut the frame as a V laying on its side.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site serviceableness, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title what is the proper way to splice a truck frame by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.